Die designing, forging, machining, and finishing — all of the manufacturing processes — are operated by a single integrated production system implemented within the company. High quality products are manufactured within a short delivery period with seamless coordination at each production stage.

“How to manufacture high quality products with the least amount of material in a fast and consistent manner.” Nakano Forging has set this as our ultimate mission, and has developed an original integrated production system to put it into practice. The system not only utilizes a thorough quality control check of products, but it also quickly responds to defects found in trial productions, which has made faster delivery of products possible. Also, by utilizing advanced equipment from Europe combined with our skilled craftsmanship, we have successfully produced products with an accuracy of less than or equal to 0.05 mm* deviation in die alignment and 0.1mm* deviation in hollow punch core — a precision unmatched by any other company.

(*ration provided by Nakano Forging Co., Ltd.)

Production, forging, machining surface treatments, and designing die casts; all of the essential facilities are provided within the company. We have experienced engineers who are trained to operate our advanced systems with ease. Our high-precision products are manufactured via a seamless coordination of multiple processes which can only be achieved by an integrated manufacturing system.

Advanced machines from Europe are used to make this level of precision forging possible. We painstakingly control the quality of our products at the processing level — We even make our own chucking jigs used for the machining of dies. As a result, we have managed to achieve precision machining by units of 10 microns.

We have established a department dedicated to the designing and production of dies which is essential for the quality finishing of high precision products. The dies are produced in close coordination with the production sites. By using the high performance CAD/CAM system, the die information is maintained in a digital data format. As a result, we can efficiently support repeat orders.

We have standardized the know-how of craftsmen, on whom we have traditionally relied on for their experience, intuition, and ability to make on-site decisions (such as type and quantity of die releasing agents to be applied, and temperature adjustments) during the production process.

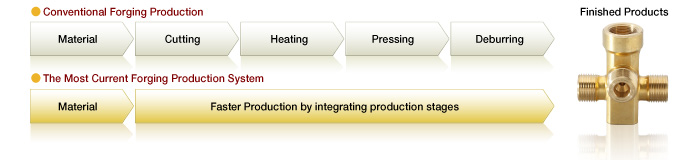

We have completely eliminated inefficiencies from various production processes, of which many have been regarded as the norm in forging manufacturing. By integrating the conventional forging processes, such as cutting, heating, forging, and deburring, we have succeeded in developing a process to produce hollow die cast forged products with no burs. The dies used for this technology are designed by CAD/CAM, and produced by a vacuumed quenching method which helps to minimize distortions. In the finishing process, the forged product is polished in detailed precision by a skilled craftsman.

With the newly developed precision die technology and centralized management system operated by a dedicated computer system, we have been able to minimize defects, and to produce products of consistent quality in a shorter time period. The finished products do not contain wasteful burs that requires trimming, hence there is a substantial savings in material costs, resources, and time. Needless to say, by employing strict quality control, we guarantee the quality of our products to be even higher than before.