We, Nakano Forging Group, have continuously pursued the possibilities of nonferrous metals and challenges of various forms of forging. Our top quality forged products have received high praise from many business enterprises.

We possess a deep understanding of nonferrous material properties: brass, copper, aluminum, and stainless steel. We can efficiently process materials into any requested shape and quality using our superior hot forging skills and technology. The quality of our products surpasses that of other companies, because everything (including dies) is manufactured in-house.

Hot Forging Process

If a shape can be transferred to a die, we can produce even complicated components using brass (C3771B). Our specialty is in producing goods that weigh between ten to a few hundred grams. We can also produce trial forged goods in a minimum of 10 days. We process our products using a multiple automated forging press line as the main assembly line, and can handle both small and large lots. We are capable of manufacturing our products using an integrated production system covering all the processes, from machining through finishing.

Hot Forging Process

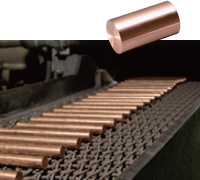

Among the nonferrous materials, copper is a material that requires the highest of skills. We mainly forge those copper materials with superior workability, such as C-1100 (Tough pitch copper) and C-1020 (Oxygen-free copper).

Hot Forging Process

Because we make our own dies, we can process aluminum and stainless steel materials, which tend to be avoided by many companies, except by those who specialize in these materials. In order to avoid contamination by other materials, we forge these materials using completely independent lines.

Our products are being employed by large manufacturers in various fields. Plumbing parts that connect pipes carrying fluids (such as water, air gas, and oil), and various valves that control machine tools, are some examples of the products for which we have received high praise. Our high quality products are employed by house builders for their water supply, drainage components, and hot water supply equipment parts. They are also used in high quality lightning rods, for Buddhist altar fittings, for builders’ hardware, and for special high pressure valves that are used in accumulators. The brass forged components are receiving special attention as environmentally friendly products due to brass’ low melting point, which makes our products easy to recycle and thus have lower CO2 emissions.